Optical Inspection Technology: How It’s Shaping Quality Control in 2025

As industries continue to push for higher precision and efficiency, optical inspection technology is revolutionizing quality control in 202Advanced imaging, artificial intelligence, and automation are enhancing defect detection, improving manufacturing accuracy, and reducing costs.

This guide explores the latest developments in optical inspection, its applications across various industries, and how businesses can leverage this technology for superior quality assurance.

Key Advancements in Optical Inspection Technology

AI-Powered Image Processing

Artificial intelligence is transforming visual inspections by enhancing accuracy and speed.

- Deep learning models for defect detection

- Automated anomaly recognition with high precision

- Real-time data analysis for instant decision-making

3D Optical Inspection

Advanced 3D imaging systems offer more precise measurements and defect identification.

- High-resolution 3D scanning for complex parts

- Surface texture and depth analysis

- Accurate dimensional inspection for tighter tolerances

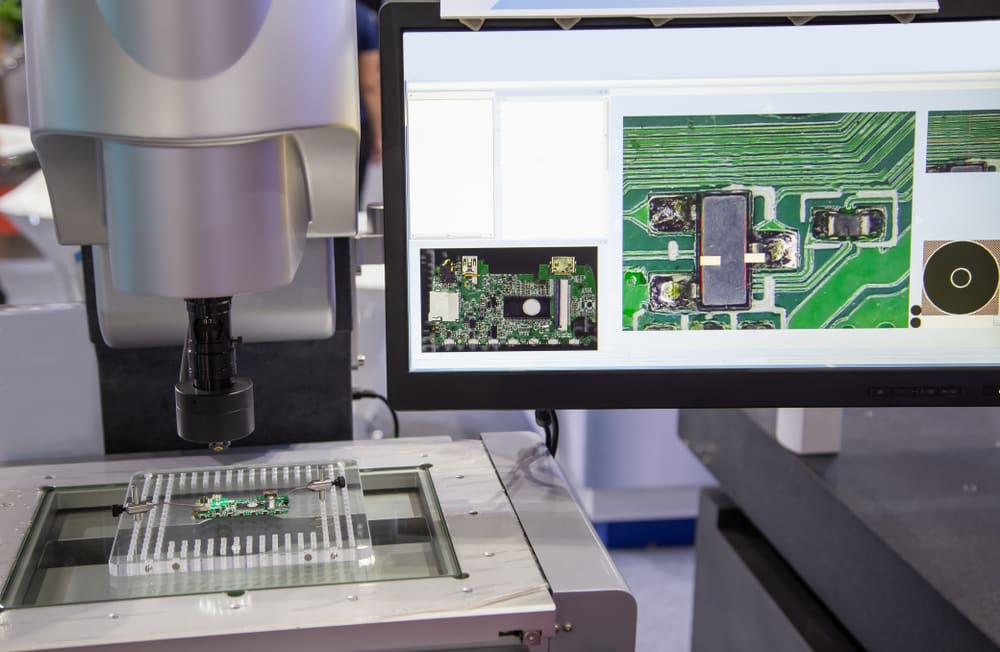

Automated Optical Inspection (AOI) Systems

Automation is streamlining quality control in manufacturing and electronics production.

- High-speed defect detection in circuit boards and components

- Integration with robotic systems for efficiency

- Real-time adjustments in production lines

Industry Applications of Optical Inspection

Electronics Manufacturing

Ensuring defect-free production of microchips, circuit boards, and other components.

- Automated quality checks for soldering and assembly

- Detection of microscopic defects in semiconductors

- Reduction of waste through real-time adjustments

Automotive Industry

Optical inspection improves safety and performance in vehicle manufacturing.

- Surface defect analysis in metal and plastic parts

- Precision measurement of engine and transmission components

- Real-time quality control on assembly lines

Pharmaceutical and Medical Devices

Ensuring compliance with strict safety regulations and product quality standards.

- Inspection of pills and packaging for defects

- Verification of medical device assembly

- Reducing contamination risks with non-contact inspection

Benefits of Optical Inspection Technology

Higher Accuracy and Consistency

Optical inspection systems provide unparalleled precision compared to human inspection.

Increased Efficiency and Speed

Automated inspections reduce production downtime and speed up quality control processes.

Cost Savings and Waste Reduction

Early defect detection prevents material wastage and costly rework.