Published on January 11, 2026

4 min read

Mastering Inventory Management Software: A Step-by-Step Guide

In an increasingly competitive business landscape, effective inventory management is crucial for success. Inventory Management Software (IMS) offers businesses a powerful tool to track, manage, and optimize inventory levels across various operations. This article delves into how to use inventory management software effectively, outlining essential features, best practices for implementation, and strategies for maximizing its benefits.Streamlining Your Business Operations with Effective Inventory Management

Understanding the Core Features of Inventory Management Software

Understanding the Core Features of Inventory Management SoftwareBefore diving into the practicalities of using inventory management software, it is vital to understand its core features.

A robust IMS should offer real-time inventory tracking, allowing businesses to monitor stock levels across multiple locations and sales channels seamlessly.

This feature ensures that you have up-to-date information on your inventory, helping to prevent stockouts and overstock situations.

Other essential capabilities include automated reorder points, barcode scanning for efficient stocktaking, and integration with other business tools such as accounting and e-commerce platforms.

By leveraging these features, businesses can maintain accurate inventory records and streamline their operations.

Choosing the Right Inventory Management Software

Selecting the right IMS is a critical step in optimizing your inventory management process.

Businesses should assess their specific needs and choose software that aligns with their operational requirements.

Key considerations include scalability—ensuring the software can grow with your business—and user-friendliness, which impacts employee adoption rates.

Additionally, look for software that offers comprehensive customer support and training resources to facilitate a smooth transition.

Many providers offer demos or trial periods, allowing businesses to evaluate functionality before making a commitment.

Implementing Best Practices for Successful Usage

Once you have selected an appropriate IMS, implementing best practices is essential for maximizing its effectiveness.

Start by centralizing your inventory data across all sales channels—this ensures that your stock levels are synchronized and reduces the risk of overselling.

It is also crucial to establish clear processes for data entry and inventory updates; consider using barcode scanning to minimize human error during these tasks.

Regular audits of your inventory can help identify discrepancies early on, ensuring that your records remain accurate over time.

Training Your Team for Optimal EfficiencyTo fully leverage the capabilities of your inventory management software, investing in training for your team is imperative.

Provide comprehensive training sessions that cover all aspects of the software, including how to enter new products, manage stock levels, and generate reports.

Encourage employees to explore the software's features and utilize them in their daily operations.

Creating a culture of continuous learning around the IMS will not only enhance efficiency but also empower employees to take ownership of their roles in inventory management.

Monitoring Performance and Making Adjustments

Finally, regularly monitoring the performance of your inventory management system is key to ongoing success.

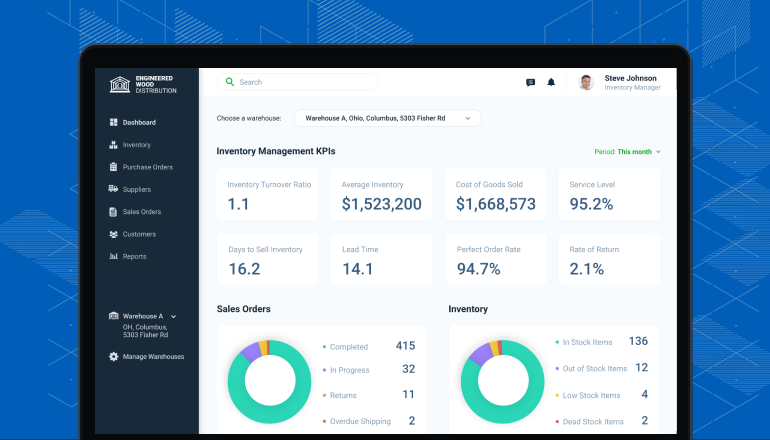

Utilize analytics tools within the software to track key performance indicators (KPIs) such as turnover rates, order accuracy, and stock levels.

By analyzing this data, businesses can identify trends and make informed decisions about purchasing and stocking strategies.

Be prepared to adjust your processes as needed—whether it involves changing reorder points based on sales forecasts or refining product listings based on customer demand.

In conclusion, effectively using inventory management software requires a strategic approach that encompasses understanding its features, selecting the right system, implementing best practices, training staff, and continuously monitoring performance.

By following these guidelines, businesses can enhance their operational efficiency, reduce costs associated with excess inventory or stockouts, and ultimately improve customer satisfaction through better service delivery.